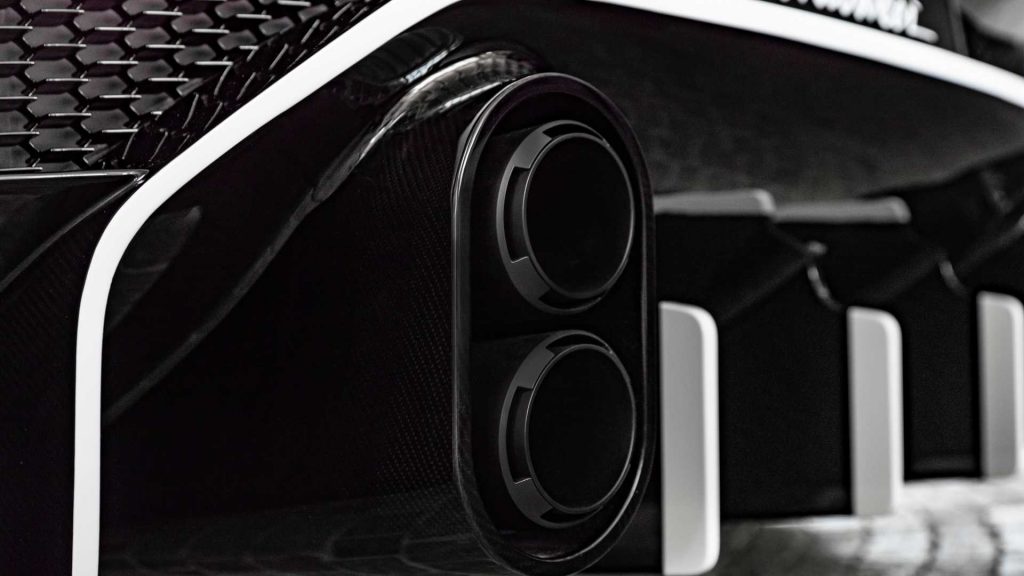

Everything about Bugatti is premium. From the immense quad-turbo W16 engine down, the uber-high quality interior and the exhaust tip covers.

Bugatti uses a 3D printer to make the Titanium covers so they are as thin and as light as possible. The covers first used on the Chiron Pur Sport weigh just 1.85 kg making them 1.2 kg less than the covers on the regular Chiron.

Bugatti used four 400-watt lasers to print the titanium parts. It’s thinnest point measures just 0.4 millimetres thick as the process stacks 4,200 layers of metal powder that are then fused together.

Another added benefit of the titanium covers is their ability to withstand heat (over 650 degrees Celsius) protecting the component from extreme exhaust temperatures.

Once its produced, Bugatti checks the quality before blasting it with corundum and adding a high-temperature black-ceramic paint finish to complete the look.