A well-known method to increase the gas mileage of a car is called ‘Cylinder Deactivation”. It’s a technology that has been used many times over the years with varying degrees of success. Conceptually it is simple. Let’s say you have an 8 cylinder engine. With cylinder deactivation technology, you use all eight cylinders when full power is needed and “deactivate” half of them so only 4 are used when cruising. This allows one access full power when needed yet you can enjoy the gas mileage of a small engine when cruising. The service technicians at www.griffismotors.net helped explain to us the technical reasons behind how it saves gas:

A well-known method to increase the gas mileage of a car is called ‘Cylinder Deactivation”. It’s a technology that has been used many times over the years with varying degrees of success. Conceptually it is simple. Let’s say you have an 8 cylinder engine. With cylinder deactivation technology, you use all eight cylinders when full power is needed and “deactivate” half of them so only 4 are used when cruising. This allows one access full power when needed yet you can enjoy the gas mileage of a small engine when cruising. The service technicians at www.griffismotors.net helped explain to us the technical reasons behind how it saves gas:

In typical light load driving (e.g. highway cruising) with large displacement engines, only about 30 percent of an engine’s potential power is used. This is because under these circumstances, the throttle valve is only slightly open and the engine has to work hard to draw air through it. The result is an inefficient condition known as “pumping loss”. Pumping losses occur because a partial vacuum occurs between the throttle valve and the combustion chamber—and some of the power that the engine makes is used not to propel the vehicle forward, but to overcome the drag on the pistons and crank from fighting to draw air through the small opening into the engine. Deactivating cylinders under light load forces the throttle valve be opened more fully to create constant power and allows the engine to breathe easier. Better airflow reduces associated pumping losses. The result is improved combustion chamber pressure as the piston approaches top dead center. Better combustion chamber pressure means a more potent and efficient charge of power is unleashed.

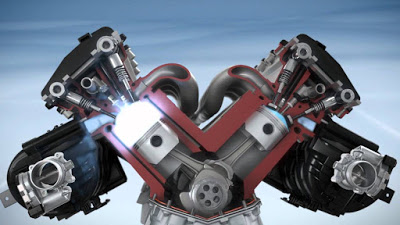

How Does it All Work? In a nutshell, cylinder deactivation is simply shutting off the intake and exhaust valves closed for a particular set of cylinders in the engine. Depending on the design of the engine, valve actuation can be controlled by one of two common methods:

- For pushrod designs -the hydraulic valve lifters are collapsed by using solenoids to alter the oil pressure delivered to the lifters. In their collapsed state, the lifters are unable to elevate the pushrods under the valve rocker arms, resulting in valves that are closed.

- For overhead cam designs – Two connected rocker arms are used. One rocker follows the cam profile while the other actuates the valve. When a cylinder is deactivated, solenoid controlled oil pressure releases a locking pin between the two rocker arms.

For both methods, fuel delivery for each deactivated cylinder is cut-off by electronically disabling the appropriate fuel injection nozzles. The transition between normal operation and deactivation is smoothed by subtle changes in ignition and camshaft timing as well as throttle position all managed by the car’s engine control module. In a well-designed and executed system, the switching back-and-forth between both modes is seamless.

Cylinder deactivation has been only used on a handful of car models over the years. In the early 80s, Cadillac had a cylinder deactivation technology that could disable 2 to 4 cylinders of their V8 engine. In the early, 2000s, DaimlerChrysler introduced their Multi-Displacement (MDS) system and today Honda offers their Variable Cylinder Management (VCM) system on select models. The process is a good one and we may see more iterations of it offered in the future.

Thanks to: Griffis Motors